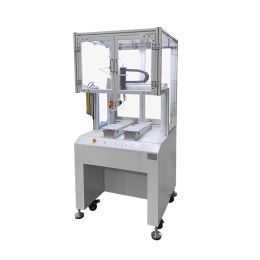

狠狠色色综合网站丨国产高清在线精品一区二区三区丨久久精品亚洲日本波多野结衣丨午夜AV内射一区二区三区红桃视频丨亚洲第一综合天堂另类专区丨欧美丰满熟妇BBB久久久丨精品欧美一区二区三区久久久丨日韩视频中文字幕精品偷拍 Selective spraying machine

HW-TFC-450-X

Selective coater

Application scope:PCB board,mobile phone,3C digital,smart wearable device,semiconductor chip,new energy,LED industry,life science,medical care,etc.

Product features

1、The frame adopts full sheet metal welding design, beautiful appearance and stable operation;

2、Using industrial computer control,WINDOWS 7 operating system is more convenient,more humanized;

3、It can be programmed online or offline;

4、With automatic accuracy calibration function,high operation accuracy;

5、Adopt imported pneumatic components for control;

6、The atomization adjustment adopts precision pressure regulating valve,which can evenly control the atomization air flow and improve the edge clarity;

7、Reserved exhaust gas emission collection port to better protect the working environment;

8、Has the function of low pressure protection,can effectively prevent low air pressure and damage to machines and workpieces;

9、The equipment is equipped with an online automatic signal connection port;

10、Pneumatic regulation filter has automatic drainage function;

11、With low air pressure report function, more safe;

12、High speed,mute effect is good,that is, can work on the board at the same time, and can spray the board,

13、The conveying belt is intelligent controlled by 2 speeds and sock back;

14、With intelligent automatic identification of on-line front and back.

Technical parameter

Frack dimensions L*W*H | L1060mm*W1300mm*H1680mm |

Weight | 720kg |

Control mode | Ndustrial control machine+board card |

Operation mode | Computerized control |

Programming mode | Visual programming |

Number of running program stores | Over 1,000 units |

PCB transmission height | 900±20mm |

Travelling speed | 0-3500mm/min adjustable |

Transfer direction | L-R(R-L) |

Transmission motor power | AC220V 40W |

PCB width range | Single board 50-450mm, spare plate 50-200mm |

Adjust the way | Manual regulation |

X.Y axis drive mode | Yaskawa servo motor+high precision wire rod, guide rail |

X.Y axis maximum running speed | 500mm/s |

X.Y axis positioning accuracy | ±0.02mm |

Z axis maximum running speed | 500mm/s |

Z axis drive mode | Yaskawa servo motor+high precision wire rod module |

Z axis positioning accuracy | 0.02mm |

Rubber valve up and down | 2SMC two-rod cylinder drive |

Number of glue valve | 2個 |

Type of glue valve | 1dispensing valve,1precision tapered valve |

PCB plate size | MAX:W450mm*L450mm |

PCB plate component height | MAX90mm |

Needle dispensing valve coating width | Minimum coating width:2mm |

Needle dispensing valve nozzle size | Optional type |

Marginal definition | ±1mm |

Fine mist flower coating width | Single coating width:6-8mm |

Cover thickness | 0.03mm-1mm |

Quantity of bucket | One three-proof paint pressure bucket+one cleaning bucket(optional) |

Cleaning function | The equipment has its own cleaning function |

Lighting part | The equipment has its own lighting light source |

Detection part | The equipment has its own UV detection light source |

Power | AC220V |

Air supply | 0.2~0.6Mpa |

Aggregate capacity | 2.5KW |